With the addition of automated robots (AGV), the factory can continuously reduce costs and increase efficiency, and further improve the tracking and optimal deployment of material information. Please check the video below for details.

Current situation of warehouse management

At present, due to the lack of sufficient information means, most of the fixed assets management is still in the primary stage of manual management. There are the following problems:

RFID / bar code intelligent warehouse management system

RFID / barcode technology is used to attach RFID / QR code labels on materials to complete digital marking.

Realize the processes of material arrival, stock in, stock in, stock out, and so on.

The on-site staff do not have to register the data one by one on the computer after moving the materials on site, so as to record the current data on the spot.

Typical application scenarios of prodog WMS

Digital management of warehouse materials

It covers three-dimensional warehouse, automatic warehouse, AGV automatic transportation, code scanning out and warehousing management, on-site material calling, etc.

Digital marking of materials

Attach RFID / bar code labels to each material to realize the digital identification of materials.

Warehouse management app

WMS system supports mobile terminal warehouse management, which is flexible, easy to use and faster.

Warehouse automation

With digital signage, warehouse automation can be easily realized. The system integrates AGV and stacker.

Whole process control

Carry out comprehensive digital management of enterprise warehouse process, covering the whole process from order to delivery.

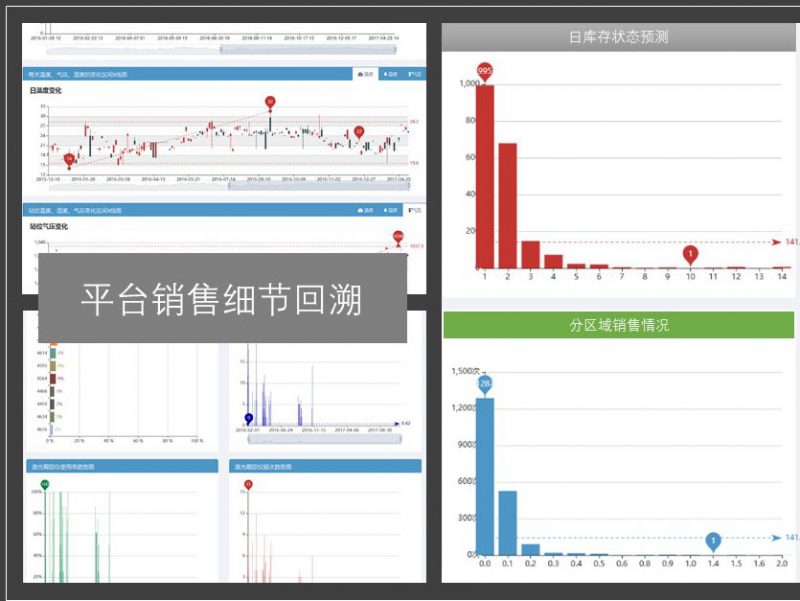

Intelligent warehouse data analysis

Provide visual electronic Kanban, inventory warning and dynamic sales rate analysis. More thorough management.

Light picking operation system

It can quickly guide the warehouse keeper to pick goods. Reduce operation error rate, improve picking efficiency and reduce picking personnel.RFID warehouse management system application video

RFID warehouse material collection + AGV

- Comprehensive digitization of warehouse materials

- AGV transport material

- Warehouse unmanned operation

Warehouse electronic Kanban

- Visual interface

- Support interface customization

- Data statistics automation

Self service receipt / issue of RFID warehouse materials

- Automatic reading of materials

- Automatic shooting scene

- Automatic receipt / issue registration

Electronic picking

- Comprehensive visual picking

- Linkage with prodog system

- Picking accuracy: 100%

Digitalization + automation of stored materials

- AGV automatic handling

- Comprehensive and accurate data

- Integrated application of RFID + AGV + system

- Workshop material digital control node

- Improve efficiency by 200% and save manpower

- Unlimited possibilities of expanding workshop digital twins

Efficient management: RFID workshop material collection, return, in and out record management, fast! accurate Precise!

Quick inventory: the efficiency is increased by more than 100 times by using RFID technology

Automatic inventory: when equipped with RFID inventory robot, the inventory does not need to be counted manually.

Automatic counting: when equipped with intelligent workshop material cabinet, counting does not need to be done manually.

Warehouse material searching: visual light picking is added to assist manual rapid realization of functions, and the management efficiency is improved by more than 100 times.

Whole life cycle: intelligent management of workshop material initialization, out / in / transfer, collection, return, handover and other links.

Fully self-service workshop material in and out management, greatly improving the efficiency of workshop material lending and return.

The background collects the material status data of the workshop in real time, scientifically analyzes and generates reports.

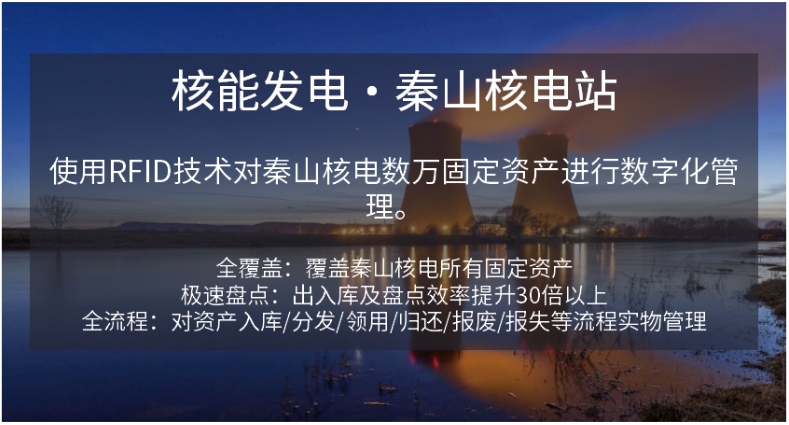

Customer application cases